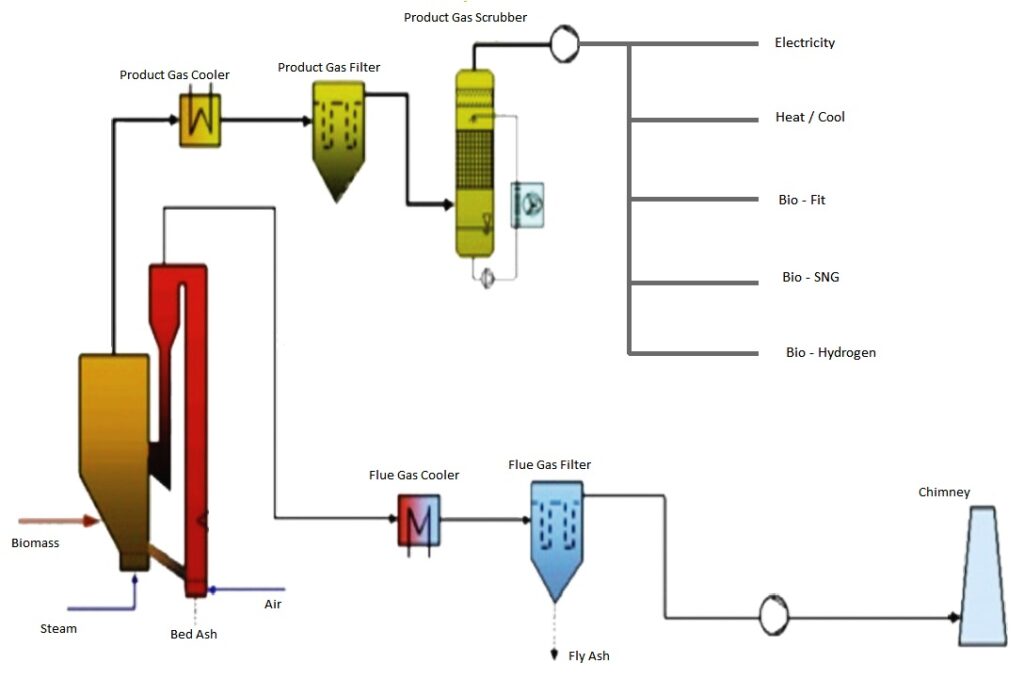

The Dual Fluidized Bed ( DFB ) Gasifier developed by Gussing Renewable GmbH (GRE) with the technology introduced by Vienna University of Technology, is considered as the most sophisticated process for the production of gas from renewable resources in the world and is state of the art. At the heart of the FICFB (Fast Internally Circulating Fluidized Bed) reactor are two interconnected fluidized bed reactors. In one, the gasification reactor, feedstock together with water vapor produces a nearly nitrogen-free, low-tar gas with high calorific value in a circulating fluidized bed at ~850° C. Coke from gasification and process residues, such as tar, are burned in the other,i.e. the combustion chamber, at ~930° C. Here the bed material (olivin sand) circulating between the two fluidized beds is heated. The bed material transfers most of the heat generated in the combustion chamber into the gasification reactor. This method achieves significantly reduced emissions compared to oxidative processes (combustion). The resulting raw gas is cooled in two stages. The heat from this process step can drive an ORC or thermoelectric generator to produce electricity. Dust is filtered from the gas and tar is washed out with biodiesel. The final product is a valuable and versatile syngas.

Residual heat can be effectively utilized for district heating ,powering cold storage or chilling plant , or hot water for boiler feeding.